Jobshadowing in IES Playmar

I attended the IES Playmar jobshadowing in June 2018 in the Spanish town of Torremolinos, near the town of Malaga.

My main mentor was ICT teacher Alfonso Ballesteros and Mr. Andrés Ángel González Medina, professor of economics .

My main mentor was ICT teacher Alfonso Ballesteros and Mr. Andrés Ángel González Medina, professor of economics .

During the six-day stay we discussed the hardware and software of our schools, the possibilities of financing the purchase of IT techniques and programs, the use of ICT in other subjects and the number of our own lessons of informatics in particular specializations.

During the stay we prepared many workshops .  The main focus was on teaching 3D programming, including

The main focus was on teaching 3D programming, including

- 3D printing / design workshop (Spatch),

- Creating web pages (WordPress, Blogger),

- Using the LibreOffice office suite for Entrepreneurship,

- networking (Cisco OS) workshop.

Other activities include the development of cooperation in the field of international projects – Social Business (using 3D Printing, CLIL in the Economy) and International ICT Competition (a booklet of examples in printed and electronic form).

Other activities include the development of cooperation in the field of international projects – Social Business (using 3D Printing, CLIL in the Economy) and International ICT Competition (a booklet of examples in printed and electronic form).

The communf interviewing students who worked on their project where they used ICT technology.

ication language was English and I also appreciate very much the possibility .

I gradually pass on the experience and knowledge transferred to my colleagues at our school and at ICT teachers’ meetings at trainings and conferences.

C2 Meeting in Budapest

Planning Activity C2 in Budapest

from 15 th to 19th October.

Organized by BGSZC Business School

Download PDF Planning here

OBJETIVES C2:

- Create opportunities for developing students’ entrepreneurial skills in international partnership.

- Improve the cooperation and friendship between our centers.

- Share working methodologies, experiences and ideas.

- Improve our formation in social networks.

- Learn about the european business network.

- Work on the collaborative techniques by entrepreneurials youth.

15.10. 2018 Monday

9:00’-9:10´ Meeting at BGSZC High School.

9:10’-9:15’ Inform the group on the planning for Monday.

9.15’-10.15’ Welcome- Presentations: students’presentation of their schools and countries.

10:15’-10:30’ Coffee Break

10:30’-11:30’ Conference: “ Challenges of Hungary in the Era of Digitalization.”

11:30’-12:00’ “Escape Room” for students

12:00’-12:15’ Short break All the teams

12:15’-13:15’ Workshop: “Edward Bono´s six hats”

13:40’-16:00’ Lunch in Trófea Restaurant.

16.10.2018 Tuesday

9:00´ – 9:10’ Meeting at BGSZC High School.

9:10’-9:15’ Informing the group on the planning for Tuesday.

9:15’-10:15´ Conference: “Financial literacy for entrepreneurship”

10:15-11:15´ Conference: “European financial system: current situation and future challenges”.

11:15’ -11:30’ Coffee Break

11:30´-13:00’ Presentation: Students will present the social entrepreneurship projects on which they will work during this course and that must be completed for the meeting in Romania.

(Each centre has to take to Budapest their projects social entrepreneurship. Their students should bring a PowerPoint presentation about their projects to All teams. ).

13:00´-14:00´ Colaborative Activity: Interviews to students of different countries about their projects. Done by the Hungarian an Spanish students through podcast technology.

14:30-16:10 Lunch at Halász Csárda Restaurant.

17.10.2018 Wednesday

8:45’-8:55’ Gathering

8:55’-9:00’ Inform the group the planning for Wednesday.

9:00´-10:00´ Conference: “Corporate Social Responsabilty: The Audi´s case by Head director Audi´s Factory.

10:00’-12:00’ Visiting Graphisoft park

12:00’-14:20’ Walking in Buda Castle

14:20´-14:30´ (Sign the way out)

14:30’- 16:00 Lunch at J.Oliver / Buda Castle

18.10.2018 Thursday

8:30’-8:40´ Gathering at Blaha

8:40’-8:45’ Inform the group the planning for Thursday.

9:00’-17:50’ Trip: One day trip at Balatonfüred/ Lake Balaton

17:50´-18:00´ (Sign the way out)

Friday 19.10.2018

8:45´-8:55’ Gathering

8:55’-9:00’ Inform the group on the planning for Friday.

9:00’- 10:10’ Presentation: “Budapest uses the success of its emerging companies to be an European technology center”

10:10′-10:30′ Evaluation:Time to fill out the evaluation´s form C2 meeting (Google Drive)

10:30’-11:10’ Documentation: M2 Documentation and Bills collection Hungarian team

11:40’- 12:40’ Visit to World informations technologies Entreprise Prezi Installations.

12:40´-12:50´ (Sign the way out)

13:15´-14:30´ Lunch

Summary of Activities.

Summary of Activities that has to be made in advance for each team for the collaborative Activities.

Each Team has to prepare and carry to Budapest C2 Meeting :

- Students’presentation of their schools and countries.

- Each centre has to take to Budapest their projects social entrepreneurship.

- Their students should bring a PowerPoint presentation.

- The interview for the podcast.

- Questions will be sent to coordinators in advance.

Arduino controlled pneumatic crushing machine

1. Introduction.

Technology evolves at an accelerated pace and companies must adapt to changes as soon as possible to generate a source of competitive advantage. The digitalization of the industry is a revolution that will change (and in fact is already doing) the paradigm of industrial manufacturing, work environments and the way of relating to both suppliers and customers.

We are at the doors of the 4th industrial revolution (Industry 4.0) and our education system must evolve to properly train future professionals.

New engineers and skilled workers will have to challenge this new era, using their skills to achieve more efficient management of resources, improve all production processes and increase profitability.

In the era of industry 4.0 and digital transformation, all young people will have to develop their talent, to foster a broad development of skills, attitudes and experiences both digital and innovation, entrepreneurship and creativity that prepare them competently for their professional future and favor your employability.

From this point of view, we find it necessary to give our students sufficient tools so that their integration into the workplace is successful and valuable for companies.

With the idea of taking another step, in the development of our project, we believe it is necessary to merge two technologies with great demand in the industry, Robotics and Pneumatics. With this, we managed to climb one more step and provide our students with the necessary skills to robotize an industrial silver.

These contents are included in the technology curriculum in 4th of that and in Industrial Technology in high school.

2. Objective and justification of the project.

“Every day, in the media, there is some news related to climate change, energy saving, depletion of raw materials, the need to recycle, …

What can we contribute to help solve this great problem that affects our entire planet? ”

This was the introduction with which a debate was opened in technology class and whose purpose was for students to become aware that we only have one planet and we must take care of it.

Many ideas came up, very good, but we focused on the importance of recycling.

The idea of manufacturing a machine to help recycle cans of soft drinks using the knowledge that students have of pneumatics and robotics was raised, and to study their feasibility to manufacture and install it, in various centers accompanied by a decalogue of Reasons why we should recycle.

With the development of this project it is intended that our students be able to:

Design, implement and program robotic systems.

Design and implement pneumatic circuits.

Encourage and actively participate in the recycling of containers.

Raise awareness about the need for energy saving and its impact on the environment.

Promote entrepreneurial culture.

The knowledge necessary to develop a project of this type is present in the curriculum of technology (in 4th of that) and industrial technology 1.

The contents treated in 4th of that, related to the project are:

Block 4: Control and robotics.

4.1. Automatic systems, characteristic components of control devices.

4.2. Basic digital and analog sensors.

4.3. Actuators

4.4. Design and construction of robots.

4.5. Degrees of freedom.

4.6. Technical characteristics.

4.7. The computer as an element of programming and control.

4.8. Basic programming languages.

4.9. Architecture and basic characteristics of control hardware platforms, advantages of free hardware over proprietary.

4.10. Application of controller cards or control hardware platforms in experimentation with designed prototypes.

4.11 3D design and printing. MAKER culture.

Block 5: Pneumatic and hydraulic.

5.1. Analysis of hydraulic and pneumatic systems.

5.2. Components

5.3. Symbology

5.4. Physical principles of operation.

5.5. Simple assemblies

5.6. Use of simulators in the design of basic circuits.

5.7. Application in industrial systems.

For the 1st year of high school the following contents are treated:

Block 4. Programming and robotics.

4.1. Programming software

4.2. Flowchart and standardized symbology.

4.3. Variables: concept and types.

4.4. Mathematical and logical operators.

4.5. Structured programming: functions.

4.6. Control structures: Loops, counters, conditionals, etc.

4.7. Sensors and actuators. Types.

4.8. Inbound treatment

4.9. Programming of a hardware platform for handling a robot or control system.

Block 5. Technological products: design and production.

5.1. Design processes and product improvement.

5.2. Phases: study, development, planning.

5.3. Project development and product manufacturing. Phases: CAD / CAM / CAE.

5.4. Standardization in design and production.

5.5. Quality management systems.

Block 6. Manufacturing procedures.

6.1. Manufacturing techniques and procedures.

6.2. New technologies applied to manufacturing processes.

6.3. 3d print.

The main objective of this project is that our students become aware of the amount of energy and raw materials necessary to create a container and as with the recycling of these we can significantly reduce energy consumption.

To help with recycling, our students are asked to design and build a machine capable of compacting soda cans for storage and subsequent transportation to a recycling center.

The idea is to start from a very basic but functional model that will be improved until it is equipped with all the functions and safety measures necessary for safe use in schools.

This work methodology, known as an incremental model, allows students to see results quickly which motivates them to continue advancing in their objectives.

3. Basic example

For information purposes, since we want the students to design the machine, a scheme of a pneumatic circuit is provided that performs the function we are looking for.

This circuit needs to be improved, incorporating sensors and intelligent control through Arduino. These improvements will provide the model with safety measures that make its use suitable in a school.

Basically it is a single acting pneumatic cylinder controlled by a 3/2 valve with pilot operation via push-button and spring return.

Arduino will check if there are cans to crush, using ultrasound or infrared sensors, and actuate the cylinder through the use of relays.

In addition, the machine must have protective measures so that its use does not pose any risk.

4. Material necessary for the development of the project.

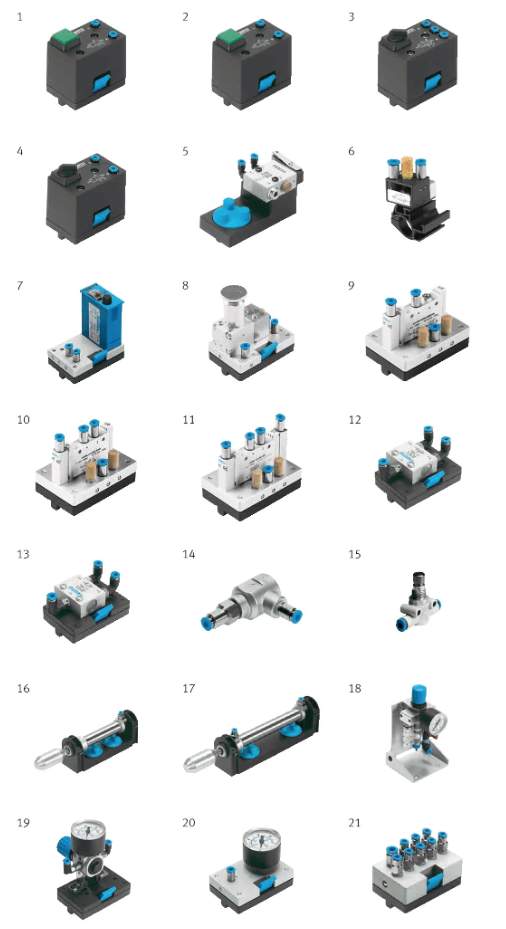

Once the circuit is designed and tested in virtual simulators, we need to assemble a prototype. For this, all pneumatic components that are normally supplied with pneumatic trainers (Cylinders, distribution valves, Compressor, Maintenance unit, solenoid valves… ..) will be used.

We show in the following images the necessary elements to assemble different designed prototypes.

As an element of control, an Arduino board and various sensors and actuators will be used. These elements will allow us to control the circuit and provide them with the necessary security measures.

The concretion of all the necessary material will depend on the designs that are made, due to this, it is necessary to have a complete equipment for the practices of pneumatic circuits in addition to various Arduino boards, sensors and actuators.

5. Methodology.

The methodology we are going to use is the Project Method.

Starting from a problem, students must seek information and propose several ideas that can solve it, once discussed in a group, the best idea is chosen and developed.

A first prototype is designed, and it is planned how we will build it, for this, a list of necessary materials and tools is made as well as the order of the operations to be carried out and who will perform them.

Once our prototype is built, we evaluate it and check if it solves our problem.

As you can see, the project method gives students the necessary tools to develop a product, which solves a problem or satisfies a need. All this knowledge can be extrapolated to everyday life and are highly valued in the workplace.